Mexican Graphene Driving a New Generation of Dental Materials

Graphenemex® shows that PMMA can be stronger, safer, and antimicrobial

Modern dentistry increasingly relies on advanced biomaterials capable of offering greater mechanical strength, improved aesthetics, and enhanced biological safety. Within this context, graphene has emerged as one of the most promising materials, and Mexico is now an active participant in this technological shift thanks to the graphene produced by Graphenemex®, a brand developed by the company Energeia Fusion.

Graphene stands out for its exceptional combination of properties, including extraordinary mechanical strength, high electrical and thermal conductivity, and remarkable chemical stability. These characteristics have attracted significant attention in biomaterials science, particularly in dentistry, where extending the lifespan of restorations, prostheses, and orthodontic appliances—while reducing the risk of infection—is a constant priority.

One of the most widely used dental materials is polymethyl methacrylate (PMMA), commonly employed in prosthetic and orthodontic applications. Despite its versatility, PMMA presents well-known limitations, such as susceptibility to fracture and microbial contamination. Recent research has demonstrated that the proper incorporation of Graphenemex® graphene can significantly transform its performance.

“This development reflects our commitment to translating advanced materials science into solutions that deliver real value for the dental industry,” says Amílcar Sala, Commercial Director of Graphenemex®. “By integrating our graphene into PMMA, we are enabling manufacturers and clinicians to access materials that combine higher durability, improved hygiene, and long-term performance, while meeting international standards of safety and quality.”

Experimental results showed that PMMA modified with Graphenemex® graphene exhibits increased fracture resistance, improved dimensional stability, and reduced wear during mastication. In practical terms, this translates into dental prostheses and devices that are more durable and reliable for patients.

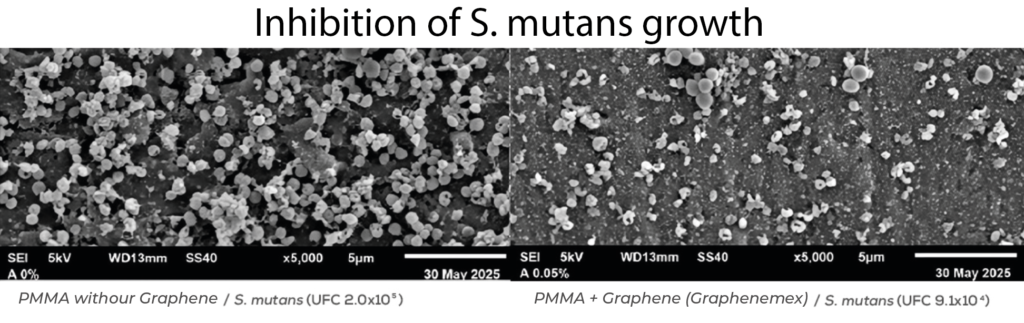

One of the most significant findings was the marked inhibition of bacterial growth, particularly Streptococcus mutans, the primary microorganism associated with dental caries. Statistical analyses revealed a highly significant difference between PMMA with and without graphene (p = 0.0001), supporting graphene’s role in enhancing the antimicrobial performance of dental materials.

According to Dr. Dania Hernández, Deputy Director of Graphenic Materials at Graphenemex®, these benefits do not compromise material safety. “One of the main challenges was ensuring biocompatibility. The studies confirmed that graphene, when properly integrated into the PMMA polymer matrix and used at controlled concentrations, is not cytotoxic and does not alter the polymer’s chemical integrity. On the contrary, it promotes a denser and more stable polymer network,” she explains.

Cytotoxicity assays conducted in accordance with ISO 10993-5 demonstrated that none of the evaluated concentrations were toxic to cells. Additionally, increased hydrophobicity—measured through contact angle analysis—helped reduce bacterial adhesion and biofilm formation without negatively affecting the material’s interaction with surrounding tissues.

These findings were generated through graduate-level research led by Dr. Juan Carlos Flores at the Nanomaterials Laboratory of the Faculty of Stomatology at the Autonomous University of San Luis Potosí (UASLP) , following international standards such as ISO 7405 and ADA Specification No. 12. This rigorous framework strengthens both the scientific validity of the results and their potential for future clinical application.

Overall, the experimental evidence positions PMMA modified with Graphenemex® graphene as a multifunctional dental biomaterial, offering mechanical, biological, and preventive advantages against oral biofilm-related pathologies. This advancement not only contributes to the evolution of modern dentistry but also reinforces Mexico’s role in the development of high-value, cutting-edge materials.