Next-generation battery may unlock the future for electric vehicles

To curb global warming, policymakers say, we need to switch from gas-powered cars to driving clean, non-polluting electric vehicles.

Major automakers plan to make that happen, promising a full line of electric vehicles by 2030. But there’s just one little speed bump on the road to electrification: We don’t have the capacity to make enough batteries for all those plug-ins.

Electric vehicle sales will jump four-fold in the U.S. in the next five years, climbing from 1.8% of all car sales in 2020 to about 7% in 2026, according to market research firm AutoPacific of Tustin. The U.S. Department of Energy projects a 5- to 10-fold increase in global EV battery demand by 2030.

Startups, university research teams and auto manufacturers are rushing to meet this demand by developing improved EV batteries that charge faster, last longer, have more energy and eliminate the use of cobalt — an important ingredient that’s increasingly rare and expensive.

At Tesla’s “Battery Day” last September, for example, company officials said they plan to develop a cobalt-free battery by 2030 that costs 56% less per kilowatt-hour to produce.On June 8, the Biden administration announced a series of steps aimed at increasing U.S. battery-making capacity, including $200 million in next year’s budget for battery research and development.

“It is imperative that the United States invests immediately in scaling up a secure, diversified supply chain for high-capacity batteries here at home,” a Department of Energy fact sheet said.

The energy department had been spending as much as $300 million on year on battery research already, leading to a number of breakthroughs across the country.

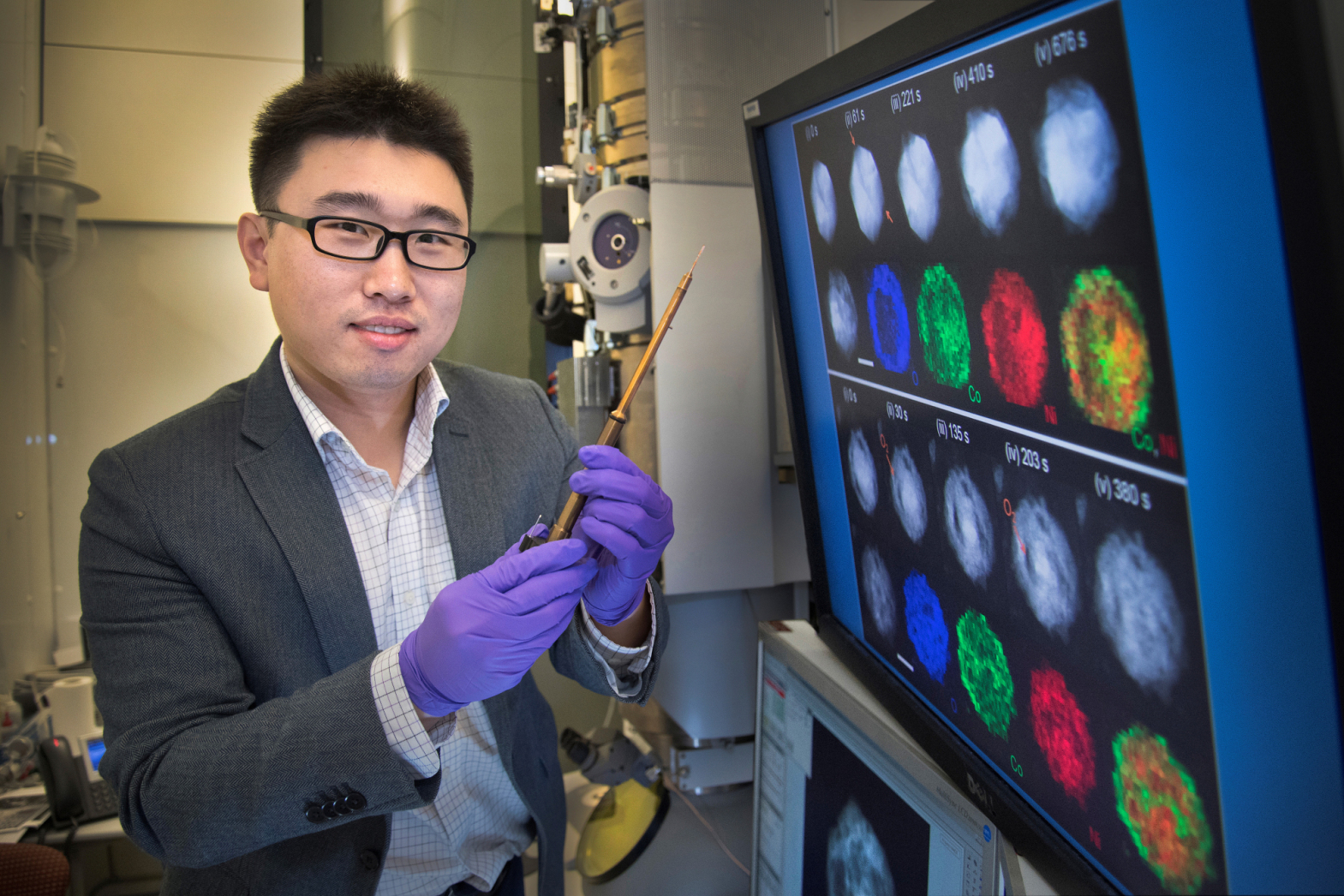

Among them, a team of scientists led by UC Irvine physicist Huolin Xin, operating under a $2.5 million DOE grant, claims to have invented a new battery chemistry that’s cobalt free and has made great advances in thermal stability.

Other advances include a research team at the University of Texas that also claims to have cracked the code for making a cobalt-free battery.

Irvine-based battery developer Enevate announced recently it signed a production license agreement to produce its new silicon-dominant EV battery featuring an extremely fast charge, high energy density (which extends an EV’s range between charges) and a manufacturing process that cuts carbon dioxide emissions by a fourth.

And a UC San Diego research team assisted by Xin has formed a company to commercialize a new material for the anode terminal that can be recharged safely within minutes for thousands of cycles.

Which one of these technologies will catch on remains to be seen. But Xin is boasting that his product has great commercial potential.

“As soon as investment comes in, it will hit its prime time,” Xin said. “In two to three years, it will dominate the market.”

We spoke with Xin, a UCI associate professor of physics and astronomy, to learn more about his invention. His comments have been edited for length.

Q: Tell us about the new electric vehicle battery your team developed?

A: I was funded by the Department of Energy to develop a high-nickel, low non-cobalt cathode (battery), primarily for EV batteries.

And the reason we wanted to develop this was cobalt is considered the black diamond in lithium-ion batteries that’s been used in pretty much all EVs. It’s like a poison pill in this industry.

Q: What’s wrong with cobalt?

A: Everyone … wants to get rid of it because cobalt is almost singularly sourced from the Republic of Congo, where they use child labor to mine this mineral.

So, all the EV companies have to do something about it, particularly Tesla. (Co-founder and CEO) Elon Musk has been saying that he wants to get rid of cobalt for this specific reason. For humanitarian reasons, primarily.

Q: What were your results?

A: My group has developed a new battery chemistry that has no cobalt, and this new material has a great cycle life that outperforms all existing cathode materials and has a thermal stability that’s top-notch. So we’ve patented this technology and we’re waiting for funding for it.

We work with three DOE national labs: Pacific Northwest, Argonne and Brookhaven National Lab. We work with these national laboratories to push lithium-ion battery technologies.

Q: How do you collaborate with them?

A: National labs are really good at making a cell that has industrial relevance. We do a lot of lab-scale testing, and they can do bigger-scale testing on an industrial-relevant scale.

Q: It is commercial ready?

A: Yes. We’re raising series A funding basically to make a start-up, … to commercialize this material.

Q: Will your cathode materials method lower or increase the cost of EV batteries?

A: It will lower the cost of EV batteries because it eliminates the expensive cobalt — expensive, toxic and inhumane cobalt.

Q: Will this technology be less prone to battery fires like we’re seeing with EVs?

A: Yes, exactly. It has a much higher thermal stability. That is the most important thing about this material that we have developed.

Q: How soon until EVs are common?

A: I think with the next wave of tax incentives from the Biden administration we will see this. First consumers will have to build a habit of buying and using EVs. And a lot of the federal funding will go to building the infrastructure, basically all the charging stations that need to be in place.

Huolin Xin at a glance

- Title: Associate professor of physics and astronomy

- Organization: UC Irvine

- Education: Bachelor’s in physics, Peking University, doctorate in physics, Cornell University

- Experience: Postdoctoral training at Lawrence Berkeley NationalLaboratory; staff scientist, Brookhaven National Laboratory